Water Level Control

Water Level Control Overview

About VackerGlobal Water Level Control

A water level indicator measures and regulates the levels of water in many distinct systems such as swimming pools, cooling towers, and water pumps/tanks, among others, based on a basic function of water flow regulation and system performance optimization. Water level controllers have numerous advantages.

The first electronic water controller, which hit the market in the early 1990s, allowing industry professionals to consistently and accurately track water levels in boilers, irrigation lakes, cooling towers, wastewater, and water tanks. However, due to their design flaws, these devices were quickly discovered to be defective. While they were quickly acknowledged as a step up over typical “toilet tank” float designs, the engineers quickly realized that long-term usage of these water controls was unlikely. Despite being more accurate, the new controllers did not allow for straightforward verification procedures, nor did they provide an intuitive user interface to allow for troubleshooting when issues arose. VackerGlobal has developed a Water Level Control System to address all of these issues.

Applications of Water Level Control System

Our Water Level Controller Product

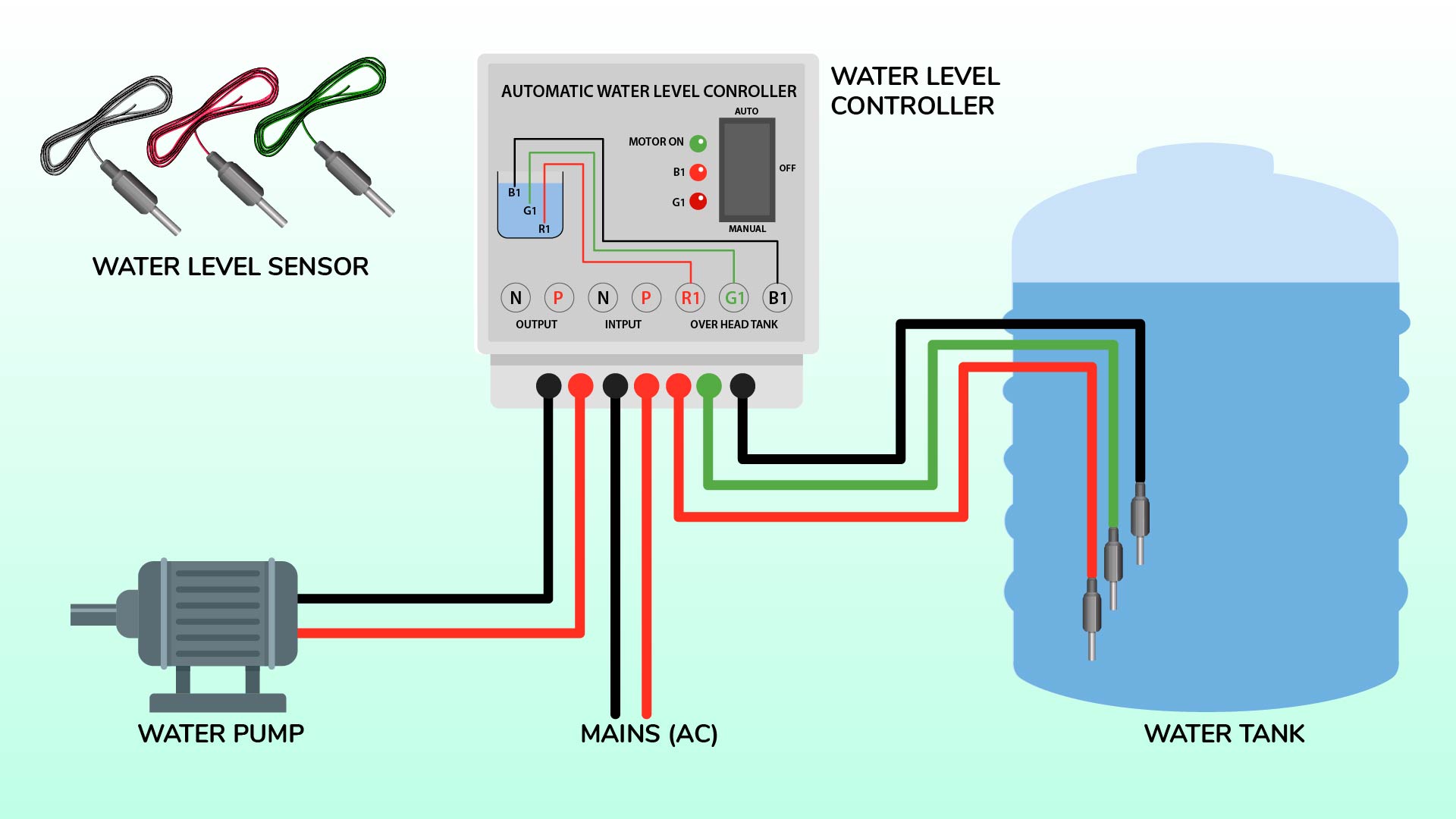

The most common sort of liquid level transmitter is a water level sensor. Any of the methods listed above can be used to monitor water levels. Ultrasound measurement and float indicators, on the other hand, are the most popular procedures. The float level switch can only indicate whether or not the water has reached the desired level. If the water level is somewhere in the middle, it can’t tell you. A float switch is the most affordable type of switch for tanks. For corrosive liquid tanks, stainless steel floats are offered. The float’s substance and stem will be stainless steel in this situation.

Benefits of Water level control system

1. Control helps prevent roof and wall leakage caused by overflowing tanks.

2. The use of an automatic system saves you time by eliminating the need for human effort.

3. Consumes very little energy, making it ideal for ongoing operations.

4. Indicates the amount of water in any form of storage tank or liquid body.

5. You can clearly hear a water alarm since it is loud.

How it works?

A water level control system is typically made up of two parts: a water level sensor and a controller. The water level sensor is usually installed near the top of the tank or reservoir, and it consists of a float that rises and falls with the water level. The controller is typically mounted near the bottom of the tank, and it contains a switch that turns the pump on and off. When the water level in the tank drops below a certain point, the float activates the switch, which turns on the pump. The pump then begins to fill up the tank until the float reaches its original position, at which point the switch is deactivated and the pump shuts off. This cycle repeats itself as needed to maintain a consistent water level.

Our Values

About Us

VackerGlobal is providing air engineering solutions for almost 10 years. Our products and services are available across the world including the USA, Europe, Middle East, and Africa. VackerGlobal is involved in all kinds of sensors, measuring instruments, monitoring systems, and control solutions for temperature, humidity & pressure. We are an ISO 9001:2015 & ISO 45001:2018 certified company trusted by multinational companies.

FAQ

Acting on a basic function of water flow regulation and system performance optimization, a water level indicator measures and manages the levels of water in multiple different systems such as swimming pools, cooling towers, and water pumps/tanks, etc. There are many advantages of water level controllers.

- Automatic: Another notable advantage with these devices is that they

regulate on their own. Eliminating manual operations with a timer switch.

- Money Saver: A water level controller helps save money by limiting the waste of water and electricity. These devices accurately regulate.

Power Saver: Living in an age where we need to be more conscious of the energy that we use, a water level controller is ideal at saving power.

Appearing on the market in the early ’90s, the first electric water controller helped industry professionals track the water levels in boilers, irrigation lakes, cooling towers, wastewater, and water tanks reliably and accurately. However, these units were soon found to be imperfect based on their design. While they did become recognized as the advancement from traditional ‘toilet tank’ float designs, the engineers soon discovered that the long-term use of these water controllers was not likely. Though more accurate, the new controllers did not provide easy verify operations nor did the units lack the intuitive user interface to enable troubleshooting when problems began.And to overcome all these, VackerGlobal has come up with their Water Level Control System. Our water level controllers come with reliable electronic design and easy installation with LED monitoring.

Water level controllers consist of automatic operation which saves manual labor time. It consumes less energy which is perfect for ongoing operations. A water alarm is loud so you can easily hear it Indicates water levels in any type of storage tank or body of liquid. It also helps avoid seepage of roofs and walls due to tanks overflowing.

Water level sensors are the most common type of liquid level transmitters.

For water level monitoring, you can use any of the above methods.

However, the most common methods are ultrasound measurement and float indicators. The float level switch can only provide a signal whether the water has reached the level or not. It cannot give an indication if the water level is somewhere in the middle. A float switch is the cheapest form of switch available for tanks. Stainless Steel floats are available for corrosive liquid tanks. In this case, the material and the stem of the float will be stainless steel.

Our Clients

Disclaimer: All trademarks mentioned in this article and images are registered trademarks of respective companies and we do not intend to misrepresent them for any benefits including financial benefits. Any other brand or product referenced on this page or any other pages fo this website is acknowledged to be a trademark of the respective holders.